Some of the next crop of wind turbines hoisted onto buildings around Chicago may come from a small manufacturing plant on the city’s North Side intent on making a big name for itself in the wind-energy business.

Andre DeRosa, 34, started a company licensing specialized wind turbines for building rooftops to manufacturers in Korea and India about seven years ago. He moved to Chicago in 2008 and started Balanced Wind LLC (www.balancedwind.com), among the first small-scale wind turbine producers to sell them in the U.S.

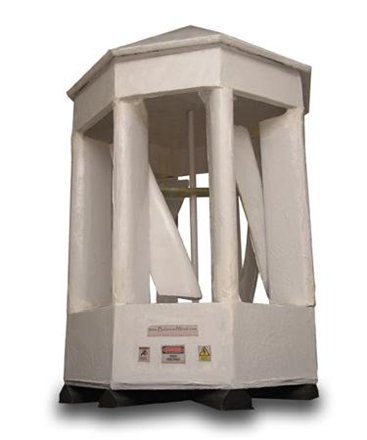

A Balanced Wind rooftop turbine

Mr. DeRosa was initially going to import the turbines from Asia, but he applied to get a piece of the American Recovery and Reinvestment Act funds to open a factory in Chicago and manufacture them on his own. To his delight, Mr. DeRosa was awarded $250,000 earlier this year. The money just started rolling in over the summer and will help pay for some computerized equipment that will speed up production at his plant, which is tucked away in a small building just off Irving Park Road.

Next month Balanced Wind will deliver its first two turbines locally to an Arlington Heights company that will mount them on its rooftop. A total of 18 turbines have been sold to clients elsewhere, including in Vermont, Hawaii, Holland and Estonia, but 12 of them are on back order.

The potential for growth is significant. There are already about 300 wind turbines fixed on top of Chicago-area buildings. Last year, Mr. DeRosa convinced 82 building owners around Chicago and northern Illinois to place wind meters atop their buildings to gather data that will determine how much energy they can potentially harness from wind currents blowing around their rooftops. He’s hoping they’ll consider the merits of buying one from Balanced Wind down the road. Mr. DeRosa expects to be producing 20 turbines a month by November and plans to boost his workforce to 45 from 17 by 2011.

Mr. DeRosa isn’t your typical renewable-energy business owner. He has a divinity degree from the Moody Bible Institute but pursued his entrepreneurial interests in wind energy and connected with engineers that had the know-how to make turbines. Still, he’s found a way to fold his commitment to social justice into his business plan: He was awarded grants from two Illinois state programs to train disadvantaged individuals who’ve had barriers to the workplace to build his wind turbines and he intends on hiring them when the 12-week training period ends this fall.

Crain’s caught up with Mr. DeRosa at his manufacturing site last week to learn why he believes his type of wind turbines will take the urban landscape by storm and how he plans to help some companies pay for his equipment.

Crain’s: How are your wind turbines different from the sleek, white ones we see on those tall poles with the three rotating blades?

Mr. DeRosa: Our turbines aren’t the ones most people think of. The ones with the tall poles are called horizontal axis. We make vertical axis turbines. What we tried to do is solve the problem of putting a turbine on the rooftop of a building where you run into birds flying into the equipment and vibration degrading the quality of the building. Our turbine sits flat on the roof of a building the same way that an HVAC system would be installed up there. About 90% of turbines on top of buildings are installed on top of poles that are fixed to the buildings.

Crain’s: Why do you believe your wind turbines are better suited for buildings in an urban environment compared to the super tall ones we see along the highway driving through downstate Illinois or up in Wisconsin?

Mr. DeRosa: Ours are more efficient because we’re designed for a city environment. Putting a turbine (on a pole) in a city can have functional problems. As an example, the wind will bend around a nearby building that’s blocking the wind flow and create turbulence, which doesn’t allow the turbine to perform well. A traditional turbine on moderate wind days, which is what we usually get in Chicago, has difficulty determining which way to face with the wind coming from multiple directions. Our turbine can accept wind from these multiple directions because it doesn’t have to turn to face the wind. We’re still very pro horizontal axis wind turbines, but they function better further out in an agricultural community where there’s more space to put the turbine on top of a pole and for the air to encounter the turbine.

Crain’s: Wind turbines are expensive and many building owners are strapped for cash even if they want to buy them. Can you compete on price compared to the large-scale (utility) wind farms and what financing options are available?

Mr. DeRosa: We’re able to build a high quality turbine cheaply and affordably. We hope to reach parity (equal price) with utility wind farms in five years. We think we’ll be able to bring the price of our wind below $2 per kilowatt hour by then. Our 10 kW wind turbine today is priced at $35,000 installed. Our goal is to get that below $20,000 in five to seven years.

The state of Illinois through the Department of Commerce and Economic Opportunity has a 30% rebate that companies can apply to receive. They just gave out about $210,000 for installed wind turbines this year and they’ll have another round available in 2011. Corporations also get federal tax credits at 30%.

Also, we’re going to begin offering financing on our 5 kW turbines. We set aside some of our own internal capital for corporate building clients that qualify under the credit.

Crain’s: Your product is part of the green economy, but do you incorporate sustainable practices in manufacturing your turbines?

Mr. DeRosa: Yes, we’ve got a really green product and we try to buy our parts locally as much as possible. The equipment comes from a supplier in Arlington Heights. The glass fiber we use for the composite cover comes from suppliers in Chicago and Countryside. We source outside the state to Rhode Island sometimes to get an earth-friendly epoxy made from cashew-nut oil, but it’s much better than the petroleum-based ones. And the footings of the turbine ares made by a Chicago company that crushes old used tires to reformulate the footings for us.

Once we get our City of Chicago permit and variance, we’ll install our own wind turbines on our building and draw all of our energy from that source. We plan on having a big ribbon-cutting ceremony, hopefully in October, and we’ll invite Gov. Pat Quinn and Rep. Mark Kirk. It’s election season so we’re hoping they’ll come.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

In other green news:

— The Department of Energy awarded $1.05 million to a new Chicago non-profit headed by prominent local business leaders that aims to boost clean-energy businesses spun off from research at the region’s universities and labs, Crain’s Chicago Business reported Thursday. The Clean Energy Trust will use the grant and local matching funds to provide seed money, business training and other support. The group is co-chaired by Nicholas Pritzker, chairman and CEO of Hyatt Development Corp., and Michael Polsky, CEO of Invenergy LLC, a Chicago-based wind power development firm. Other founders include Paula Crown of Henry Crown & Co.; Richard Sandor of the Chicago Climate Exchange; Tim Schwertfeger, former CEO of Nuveen Investments Inc.; Antonio Gracias of Valor Equity Partners, and Keith Crandell of Arch Ventures.

— A new report out this week shows that the U.S. business community is lagging behind China and other nations by more than $11 billion in creating clean-energy investments since the U.S. Senate failed to pass clean energy legislation in July. The analysis was a joint effort of the Small Business Majority, Main Street Alliance, American Businesses for Clean Energy and We Can Lead. The full report can be found here.–– A city panel on Tuesday unanimously approved subsidies to lure a big tenant to the Green Exchange, an eco-friendly real estate development in Logan Square. Crain’s Real Estate Daily brings you the full story.